After many years as a fashion entrepreneur, designer, and marketer, Pernille Fristad found herself at a crossroads. She had built and run the clothing brand Kepaza for years, designed websites, and worked closely with marketing across multiple industries.

From curious student to top-graded technical drafter: Linda Krastiņa (35) found the perfect balance between creativity and technology in the Technical Design (BIM) program at Noroff – and stepped confidently into working life with solid, real-world skills.

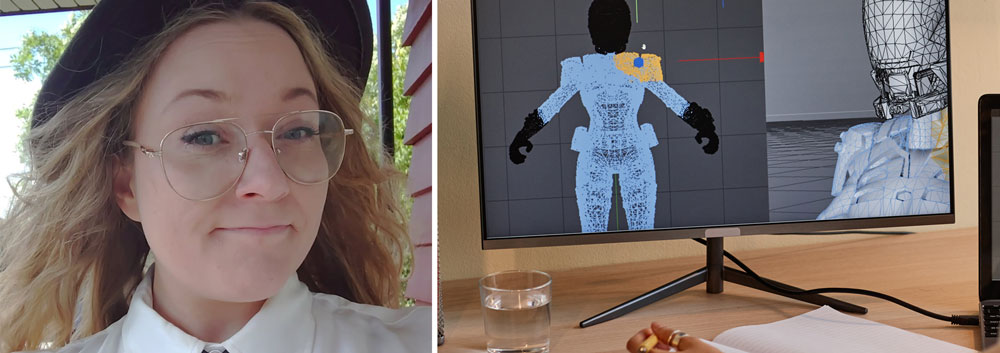

After ten years in the tattoo industry, Birna Døgg Ingudottir felt the need for a change, and to reconnect with the joy of creating. Enrolling in 3D at Noroff marked the beginning of an entirely new creative direction.